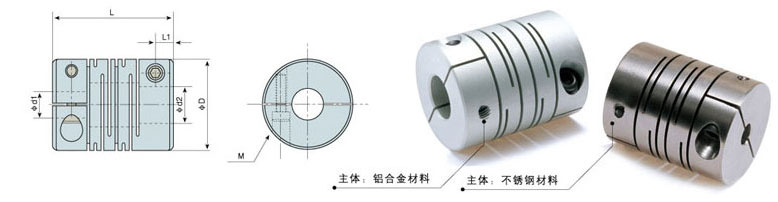

| 定位螺丝固定平行式 |

| 特性: |

|

| ●一体成型的金属弹性联轴器 |

●零回转间隙 |

| ●弹性作用补偿径向、角度、轴向偏差 |

●顺时针与逆时针回转特性完全相同 |

| ●定位螺丝固定 |

●铝合金及不锈钢材料 |

|

|

|

|

|

L |

|

M |

|

额定

扭矩

(N•m) |

最大

扭矩

(N•m) |

|

|

静态

扭矩刚性

(N•m/rad) |

|

角向

偏差

(°) |

轴向

偏差

(mm)

|

重量

(g) |

LK2-075-_ _ _ _ |

3 4 5

6 6.35 |

19.1 |

19.1 |

2.55 |

M3 |

0.7 |

0.5 |

1.0 |

10000 |

6.6×10-7 |

110 |

0.1 |

1.5 |

±0.15 |

12 |

SLK2-075-_ _ _ _ |

1.0 |

2.0 |

2.1×10-6 |

230 |

34 |

LK2-100-_ _ _ _ |

5 6 6.35

8 10 |

25.4 |

25.4 |

3.55 |

M4 |

1.7 |

1.4 |

2.8 |

10000 |

2.6×10-6 |

170 |

0.1 |

1.5 |

±0.15 |

26 |

SLK2-100-_ _ _ _ |

2.2 |

4.4 |

6.8×10-6 |

320 |

74 |

LK2-112-_ _ _ _ |

6 8

10 12.7 |

28.6 |

28.6 |

3.60 |

M5 |

1.7 |

1.6 |

3.2 |

8000 |

4.9×10-6 |

260 |

0.1 |

1.5 |

±0.15 |

42 |

SLK2-112-_ _ _ _ |

3.1 |

6.2 |

2.2×10-5 |

790 |

118 |

LK2-150-_ _ _ _ |

8 10 12

12.7 14 15 |

38.1 |

38.1 |

4.15 |

M5 |

3.8 |

4.2 |

8.4 |

8000 |

1.9×10-5 |

330 |

0.15 |

1.5 |

±0.15 |

76 |

SLK2-150-_ _ _ _ |

7.5 |

15.0 |

8.2×10-5 |

980 |

212 |

LK2-200-_ _ _ _ |

12 12.7 14

15 16 18 19

|

50.8 |

50.8 |

5.25 |

M6 |

4.0 |

9.0 |

18.0 |

6000 |

8.9×10-5 |

560 |

0.15 |

1.5 |

±0.15 |

128 |

SLK2-200-_ _ _ _ |

14.0 |

28.0 |

2.1×10-4 |

1450 |

358 |

|

|

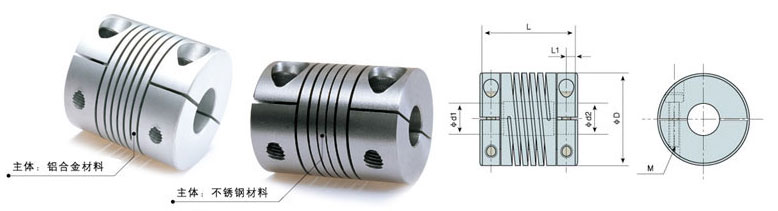

定位螺丝固定螺纹式 |

| 特性: |

|

| ●一体成型的金属弹性联轴器 |

●零回转间隙 |

| ●弹性作用补偿径向、角度、轴向偏差 |

●高弹性角向误差补偿大 |

| ●定位螺丝固定 |

●铝合金及不锈钢材料 |

|

|

|

|

|

L |

|

M |

|

额定

扭矩

(N•m) |

最大

扭矩

(N•m) |

|

|

静态

扭矩刚性

(N•m/rad) |

|

角向

偏差

(°) |

轴向

偏差

(mm) |

重量

(g) |

LK2-075-_ _ _ _M |

3 4 5

6 6.35

|

19.1

|

19.1 |

2.55 |

M3 |

0.7 |

0.5 |

1.0 |

10000 |

6.9×10-7 |

110 |

0.1 |

2.0

|

±0.15

|

12 |

SLK2-075-_ _ _ _M |

1.0 |

2.0 |

2.2×10-6 |

230 |

36 |

LK2-100-_ _ _ _M |

5 6 6.35

8 10

|

25.4

|

25.4 |

3.55 |

M4 |

1.7 |

1.4 |

2.8 |

1000 |

2.8×10-6 |

170 |

0.1 |

2.0 |

±0.15

|

28 |

SLK2-100-_ _ _ _M |

2.2 |

4.4 |

7.0×10-6 |

320 |

76 |

LK2-112-_ _ _ _M |

6 8

10 12.7

|

28.6 |

28.6 |

3.60 |

M5 |

1.7 |

1.6 |

3.2 |

8000 |

5.1×10-6 |

260 |

0.1

|

2.0

|

±0.15

|

44 |

SLK2-112-_ _ _ _M |

3.1 |

6.2 |

2.3×10-5 |

790 |

120 |

LK2-150-_ _ _ _M |

8 10 12

12.7 14 15

|

38.1 |

38.1 |

4.15 |

M5 |

3.8 |

4.2 |

8.4 |

8000 |

2.1×10-5 |

330 |

0.1 |

2.0

|

±0.15

|

78 |

SLK2-150-_ _ _ _M |

7.5 |

15.0 |

8.3×10-5 |

980 |

214 |

LK2-200-_ _ _ _M |

12 12.7 14

15 16 18 19 |

50.8 |

50.8 |

5.25 |

M6 |

4.0 |

9.0 |

18.0 |

6000 |

9.0×10-5 |

560 |

0.1 |

2.0 |

±0.15 |

130 |

SLK2-200-_ _ _ _M |

14.0 |

28.0 |

2.7×10-4 |

1450 |

363 |

|

|

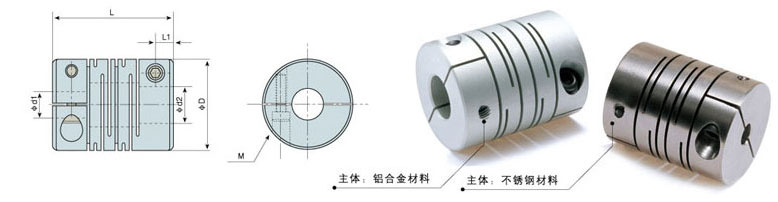

夹紧螺丝固定平行式 |

| 特性: |

|

| ●一体成型的金属弹性联轴器 |

●零回转间隙 |

| ●弹性作用补偿径向、角度、轴向偏差 |

●顺时针与逆时针回转特性完全相同 |

| ●夹紧螺丝固定方式 |

●铝合金及不锈钢材料 |

|

|

|

|

|

|

|

M |

|

额定

扭矩

(N•m) |

最大

扭矩

(N•m) |

|

|

静态

扭矩刚性

(N•m/rad) |

|

角向

偏差

(°) |

|

|

LK2-C075-_ _ _ _ |

3 4 5

6 6.35

|

19.1

|

22.9 |

3.10 |

M2.5 |

1.0 |

0.5 |

1.0 |

8000 |

9.0×10-7 |

110 |

0.1 |

1.5

|

±0.15

|

14 |

SLK2-C075-_ _ _ _ |

1.0 |

2.0 |

2.3×10-6 |

230 |

40 |

LK2-C100-_ _ _ _ |

5 6 6.35

8 10

|

25.4

|

31.8 |

4.15 |

M3 |

1.5 |

1.4 |

2.8 |

6000 |

2.5×10-6 |

170 |

0.1 |

1.5 |

±0.15

|

32 |

SLK2-C100-_ _ _ _ |

2.2 |

4.4 |

7.2×10-6 |

320 |

90 |

LK2-C112-_ _ _ _ |

6 6.35 8

10 12.7

|

28.6 |

38.1 |

5.00 |

M3 |

2.0 |

1.6 |

3.2 |

5000 |

8.8×10-6 |

260 |

0.1

|

1.5

|

±0.15

|

46 |

SLK2-C112-_ _ _ _ |

3.1 |

6.2 |

2.4×10-5 |

790 |

128 |

LK2-C150-_ _ _ _ |

8 10 12

12.7 14 15

|

38.1 |

41.3 |

5.90 |

M5 |

4.0 |

4.2 |

8.4 |

4500 |

3.0×10-5 |

330 |

0.1 |

1.5

|

±0.15

|

92 |

SLK2-C150-_ _ _ _ |

7.5 |

15.0 |

8.4×10-5 |

980 |

256 |

LK2-C200-_ _ _ _ |

12 12.7 14

15 16 18 19 |

50.8 |

51.0 |

6.70 |

M6 |

7.5 |

9.0 |

18.0 |

4500 |

9.6×10-5 |

560 |

0.1 |

1.5 |

±0.15 |

136 |

SLK2-C200-_ _ _ _ |

14.0 |

28.0 |

2.8×10-4 |

1450 |

380 |

|

|

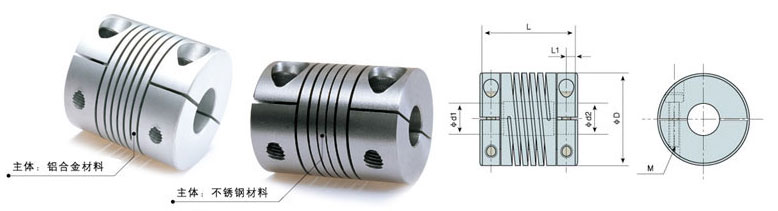

夹紧螺丝固定螺纹式 |

| 特性: |

|

| ●一体成型的金属弹性联轴器 |

●零回转间隙 |

| ●弹性作用补偿径向、角度、轴向偏差 |

●夹紧螺丝固定方式 |

| ●铝合金及不锈钢材料 |

|

|

|

|

|

|

|

|

M |

|

额定

扭矩

(N•m) |

最大

扭矩

(N•m) |

|

|

静态

扭矩刚性

(N•m/rad) |

|

角向

偏差

(°) |

|

|

LK2-C075-_ _ _ _M |

3 4 5

6 6.35

|

19.1

|

22.9 |

3.10 |

M2.5 |

1.0 |

0.5 |

1.0 |

8000 |

9.0×10-7 |

110 |

0.1 |

2.0

|

±0.15

|

14 |

SLK2-C075-_ _ _ _M |

1.0 |

2.0 |

2.4×10-6 |

230 |

40 |

LK2-C100-_ _ _ _M |

5 6 6.35

8 10

|

25.4

|

31.8 |

4.15 |

M3 |

1.5 |

1.4 |

2.8 |

6000 |

2.6×10-6 |

170 |

0.1 |

2.0 |

±0.15

|

34 |

SLK2-C100-_ _ _ _M |

2.2 |

4.4 |

7.3×10-6 |

320 |

96 |

LK2-C112-_ _ _ _M |

6 6.35 8

10 12.7

|

28.6 |

38.1 |

5.00 |

M3 |

2.0 |

1.6 |

3.2 |

5000 |

8.9×10-6 |

260 |

0.1

|

2.0

|

±0.15

|

48 |

SLK2-C112-_ _ _ _M |

3.1 |

6.2 |

2.6×10-5 |

790 |

134 |

LK2-C150-_ _ _ _M |

8 10 12

12.7 14 15

|

38.1 |

41.3 |

5.90 |

M5 |

4.0 |

4.2 |

8.4 |

4500 |

3.2×10-5 |

330 |

0.1 |

2.0

|

±0.15

|

96 |

SLK2-C150-_ _ _ _M |

7.5 |

15.0 |

8.6×10-5 |

980 |

268 |

LK2-C200-_ _ _ _M |

12 12.7 14

15 16 18 19 |

50.8 |

51.0 |

6.70 |

M6 |

7.5 |

9.0 |

18.0 |

4500 |

9.8×10-5 |

560 |

0.1 |

2.0 |

±0.15 |

140 |

SLK2-C200-_ _ _ _M |

14.0 |

28.0 |

3.0×10-4 |

1450 |

392 |

|

| |

|