|

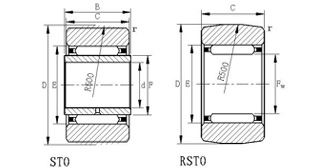

支承滚轮轴承 Needle Roller Track Roller Bearings RSTO,STO系列 |

|

| 外径 | 型号 | 重量 | 型号 | 重量 | 尺寸 | 基本额定载荷 | 极限转速 | |||||||

| Outside | Designation | Mass | Designation | Mass | Dimensions | Basic Load Ratings | Limiting | |||||||

| Diameter | (不带内圈) | (带内圈) | d | D | C | B | Fw | E | r | 动 Cr | 静 Cor | Speed | ||

| F | Dynamic | Static | grease | |||||||||||

| mm | g | g | min. | kN | kN | rpm | ||||||||

| 16 | RSTO 5TN | 8.5 | —— | — | — | 16 | 7.8 | — | 7 | 10 | 0.3 | 2.55 | 2.55 | 16000 |

| 19 | RSTO 6TN | 12.5 | STO 6TN | 17 | 6 | 19 | 9.8 | 10 | 10 | 13 | 0.3 | 3.75 | 4.50 | 10000 |

| 24 | RSTO 8TN | 21.0 | STO 8TN | 26 | 8 | 24 | 9.8 | 10 | 12 | 15 | 0.3 | 4.20 | 5.50 | 8000 |

| 30 | RSTO 10 | 42.0 | STO 10 | 49 | 10 | 30 | 11.8 | 12 | 14 | 20 | 0.3 | 8.40 | 9.20 | 5500 |

| 32 | RSTO 12 | 49.0 | STO 12 | 57 | 12 | 32 | 11.8 | 12 | 16 | 22 | 0.3 | 8.90 | 10.10 | 4500 |

| 35 | RSTO 15 | 50.0 | STO 15 | 63 | 15 | 35 | 11.8 | 12 | 20 | 26 | 0.3 | 9.10 | 10.70 | 3300 |

| 40 | RSTO 17 | 88.0 | STO 17 | 107 | 17 | 40 | 15.8 | 16 | 22 | 29 | 0.3 | 14.30 | 17.70 | 2800 |

| 47 | RSTO 20 | 130.0 | STO 20 | 152 | 20 | 47 | 15.8 | 16 | 25 | 32 | 0.3 | 16.20 | 21.50 | 2400 |

| 52 | RSTO 25 | 150.0 | STO 25 | 177 | 25 | 52 | 15.8 | 16 | 30 | 37 | 0.3 | 16.50 | 22.90 | 1800 |

| 62 | RSTO 30 | 255.0 | STO 30 | 308 | 30 | 62 | 19.8 | 20 | 38 | 46 | 0.6 | 23.30 | 35.00 | 1300 |

| 72 | RSTO 35 | 375.0 | STO 35 | 441 | 35 | 72 | 19.8 | 20 | 42 | 50 | 0.6 | 25.50 | 40.00 | 1100 |

| 80 | RSTO 40 | 420.0 | STO 40 | 530 | 40 | 80 | 19.8 | 20 | 50 | 58 | 1.0 | 35.00 | 59.30 | 850 |

| 85 | RSTO 45 | 453.0 | STO 45 | 576 | 45 | 85 | 19.8 | 20 | 55 | 63 | 1.0 | 25.50 | 43.00 | 750 |

| 90 | RSTO 50 | 481.0 | STO 50 | 617 | 50 | 90 | 19.8 | 20 | 60 | 68 | 1.0 | 43.60 | 83.40 | 650 |

| 说明: | ||||||||||||||

| 1.表中所列基本额定载荷、极限转速和重量,仅供选择参考用。 | ||||||||||||||

| 2.轴承的保持架如由塑料制成,在型号后加TN,允许工作温度:120℃连续,180℃短期。 | ||||||||||||||

| 3.脂润滑时,极限转速为表列数值的30%。 | ||||||||||||||

| Note: | ||||||||||||||

| 1.These load, speed and mass is reference of choice only. | ||||||||||||||

| 2.If the cages are made of plastics, the maximum allowable working themperrature is 120℃ in | ||||||||||||||

| continuous working and 180℃ in short working. | ||||||||||||||

| 3.With grease lubrication, 30% of these limiting speed will apply. | ||||||||||||||