|

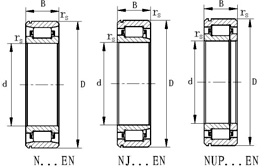

圆柱滚子轴承 Cylindrical Roller Bearings N…EN, NJ…EN, NUP…EN 系列 |

|

| 轴径 | 型号 | 重量 | 尺寸 | 基本额定载荷 | 极限转速 | 原有型号 | |||||

| Shaft | Designation | Mass | Dimensions | Basic Load Ratings | Limiting | Original | |||||

| Diameter | d | D | B | r1 | r | 动 Cr | 静 Cor | Speed | Designation | ||

| Dynamic | Static | ||||||||||

| mm | g | min. | min. | kN | kN | rpm | |||||

| 20 | N 204EN | 140 | 20 | 47 | 14 | 1.0 | 0.6 | 14.7 | 7.4 | 15000 | 202204E |

| NJ 204EN | 140 | 20 | 47 | 14 | 1.0 | 0.6 | 14.7 | 7.4 | 15000 | 262204E | |

| NUP204EN | 140 | 20 | 47 | 14 | 1.0 | 0.6 | 14.7 | 7.4 | 15000 | 192204E | |

| N 304EN | 201 | 20 | 52 | 15 | 1.1 | 0.6 | 20.5 | 10.4 | 12000 | 202304E | |

| NJ 304EN | 201 | 20 | 52 | 15 | 1.1 | 0.6 | 20.5 | 10.5 | 12000 | 262304E | |

| NUP304EN | 201 | 20 | 52 | 15 | 1.1 | 0.6 | 20.5 | 10.4 | 12000 | 192304E | |

| 25 | N 205EN | 148 | 25 | 52 | 15 | 1.0 | 0.6 | 16.8 | 8.8 | 12000 | 202205E |

| NJ 205EN | 148 | 25 | 52 | 15 | 1.0 | 0.6 | 16.8 | 8.8 | 12000 | 262205E | |

| NUP205EN | 134 | 25 | 52 | 15 | 1.0 | 0.6 | 16.8 | 8.8 | 12000 | 192205E | |

| N 305EN | 298 | 25 | 62 | 17 | 1.1 | 0.6 | 28.6 | 15.0 | 9500 | 202305E | |

| NJ 305EN | 298 | 25 | 62 | 17 | 1.1 | 0.6 | 28.6 | 15.0 | 9500 | 262305E | |

| NUP305EN | 256 | 25 | 62 | 17 | 1.1 | 0.6 | 28.6 | 15.0 | 9500 | 192305E | |

| 30 | N 206EN | 240 | 30 | 62 | 16 | 1.0 | 0.6 | 22.4 | 12.0 | 10000 | 202206E |

| NJ 206EN | 211 | 30 | 62 | 16 | 1.0 | 0.6 | 22.4 | 12.0 | 10000 | 262206E | |

| NUP206EN | 214 | 30 | 62 | 16 | 1.0 | 0.6 | 22.4 | 12.0 | 10000 | 192206E | |

| N 306EN | 410 | 30 | 72 | 19 | 1.1 | 1.1 | 36.9 | 20.0 | 8500 | 202306E | |

| NJ 306EN | 410 | 30 | 72 | 19 | 1.1 | 1.1 | 36.9 | 20.0 | 8500 | 262306E | |

| NUP306EN | 410 | 30 | 72 | 19 | 1.1 | 1.1 | 36.9 | 20.0 | 8500 | 192306E | |

| 35 | N 207EN | 298 | 35 | 72 | 17 | 1.1 | 0.6 | 31.9 | 17.6 | 9000 | 202207E |

| NJ 207EN | 297 | 35 | 72 | 17 | 1.1 | 0.6 | 31.9 | 17.6 | 9000 | 262207E | |

| NUP207EN | 339 | 35 | 72 | 17 | 1.1 | 0.6 | 31.9 | 17.6 | 9000 | 192207E | |

| N 307EN | 516 | 35 | 80 | 21 | 1.5 | 1.1 | 44.6 | 25.0 | 8000 | 202307E | |

| NJ 307EN | 526 | 35 | 80 | 21 | 1.5 | 1.1 | 44.6 | 25.0 | 8000 | 262307E | |

| NUP307EN | 562 | 35 | 80 | 21 | 1.5 | 1.1 | 44.6 | 25.0 | 8000 | 192307E | |

| 40 | N 208EN | 376 | 40 | 80 | 18 | 1.1 | 1.1 | 41.8 | 24.0 | 8500 | 202208E |

| NJ 208EN | 381 | 40 | 80 | 18 | 1.1 | 1.1 | 41.8 | 24.0 | 8500 | 262208E | |

| NUP208EN | 392 | 40 | 80 | 18 | 1.1 | 1.1 | 41.8 | 24.0 | 8500 | 192208E | |

| N 308EN | 650 | 40 | 90 | 23 | 1.5 | 1.1 | 56.1 | 32.5 | 6700 | 202308E | |

| NJ 308EN | 640 | 40 | 90 | 23 | 1.5 | 1.1 | 56.1 | 32.5 | 6700 | 262308E | |

| NUP308EN | 726 | 40 | 90 | 23 | 1.5 | 1.1 | 56.1 | 32.5 | 6700 | 192308E | |

| 说明: | |||||||||||

| 1.表中所列基本额定载荷、极限转速和重量,仅供选择参考用。 | |||||||||||

| 2.轴承的保持架如由塑料制成,在型号后加TN,允许工作温度:120℃连续,150℃临时,180℃短期。 | |||||||||||

| 3.脂润滑时,极限转速为表列数值的60%。 | |||||||||||

| Note: | |||||||||||

| 1.These load, speed and mass is reference of choice only. | |||||||||||

| 2.If the cages are made of plastics, suffix "TN" is added to the bearing No.,the maximum | |||||||||||

| allowable working themperrature is 120℃ in continuous working ,150℃ in temporary | |||||||||||

| working and 180℃ in short working. | |||||||||||

| 3.With grease lubrication, 60% of these limiting speed will apply. | |||||||||||